Make Good Use of Limited Resources, Create Maximum Profits

Tnet's professional manufacturing process consulting team can directly find reasons behind idle and misuse of a company's resources. With resource integration planning, optimization measures of equipment and implementation, we can help our client to maximize manufacturing efficiency.

Process diagnosis

Explore manufacturing process through diverse methods such as interviews and spot checks on site. From operation details, we can analyze key factors affecting overall process, overlook general operating procedures to rationalize operation, diagnose process weakness and offer suggestions for improvements.

Process improvement

We help to optimize cost structure for procedural weaknesses improvement base on process analysis and required schedule and cost. We also help to rectify vertical and horizontal procedure connections, solve procedure problems to enhance manufacturing performances and efficiency.

CASE STUDY

Diagnose the problem of traditional apparel manufactories and optimize the process via introducing equipment for lean product process

CASE STUDY

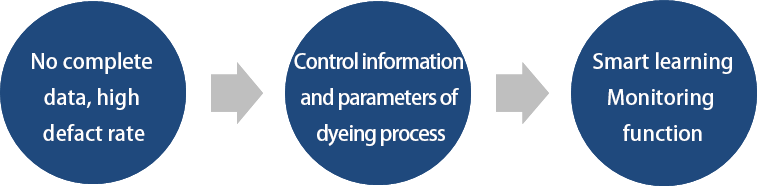

Process improvement for dyeing factory: Problem diagnosis of traditional dyeing and finishing factory and introduction of automatic equipment into processes

- Process diagnosis: Employee interview and consensus workshop

- Process improvement: Automatic process construction